Star Peak Project

U.S.A

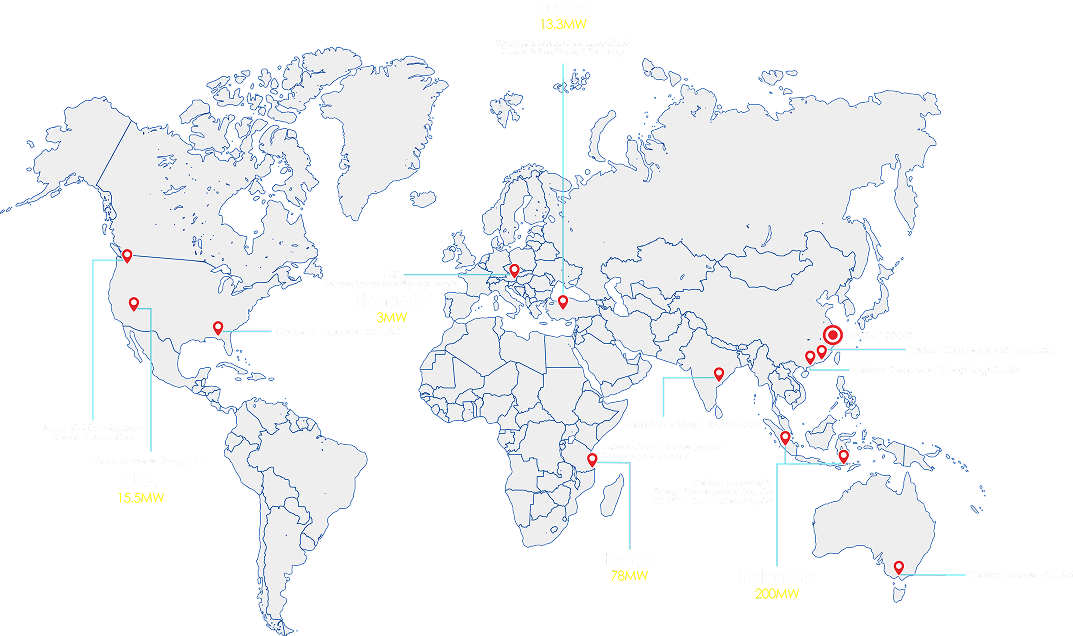

KS Orka applies modular power plant technology from Kaishan Manufacture in all projects. Kaishan Group, our sponsor, has 60 years of experience in design, research and development, production, service, and general machinery solutions, including screw expanders.

Billion RMB Assets As of Dec.2020

Number of Group Members

Number of Employees

Hectares Plant Floor Area

As the largest air compressor manufacturer in Asia and the second-largest worldwide, Kaishan is ranked the highest in sales and production scale in China. With numerous and wide-ranging industry experience to improve the performance of our screw expanders, we optimize the reliability from a technical perspective by maximizing generation capacity and utilizing the minimum thermal energy consumption while reducing cost.

Kaishan ORC Screw Expander uses an organic medium such as working fluid; preventing the use of diesel or gasoline during operation, and achieving thermo technical conversion without emission, consumption, or pollution. The power generated by the plant can be directly connected to the power grid when the original power supply and operation methods are maintained, making our technology genuinely green and environmentally friendly.

Our technology has a wide heat source application range, from steam, steam- water mixture, hot water , and other thermal fluids, with its excellent ability to adapt to variable working conditions. It has low maintenance cost as the equipment is free from overhaul for dozens of years, easy for minor repair, maintenance, and operation, and very convenient to install and move without disrupting the user' s original system. More importantly , our technology is safe and reliable; with a three-phase asynchronous and synchronous generator, the electric energy is directly inputted into the power grid to drive all-electric equipment after power grid connection and power transmission without causing any adverse effect on the power supply quality of the power grid. In the event of an emergency, the safety protection device of the generator system will be automatically disconnected from the power grid to ensure the safety of the power grid and generator.